In recent years, fiber laser cutting has made a significant impact in the world of metal cutting. The technology, while relatively new, is experiencing an industry-wide growth that outpaces other forms of laser cutting, mostly due to the advantages it offers.

If you’re unfamiliar with fiber laser cutting, here are some things you should know about this revolutionary technology:

How It Works

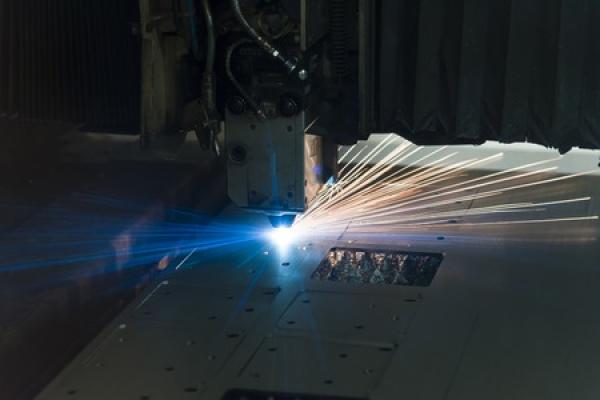

As opposed to other types of laser cutting techniques that use gas or a liquid, fiber lasers use a solid gain medium. Fiber lasers create light using laser diodes. These diodes then guide that light into a fiber-optic cable and ensure it goes in one direction, using the fiber’s core and cladding. The core will contain a rare Earth element, which will ensure that the light travels at a specific wavelength.

The light then travels to the laser cavity, which converts it to a specific wavelength and amplifies it. The photons (light) that leave the cavity then form a laser beam that should be extremely well-guided. At this point, the cutting can begin.

The Advantages It Offers

Part of the reason that laser cutting has become so popular in recent years is the many advantages it offers over other types of laser cutting services. For starters, the performance is key. Cutting sheet metal isn’t like cutting a piece of paper – it’s more difficult and far more expensive if a mistake is made or the quality isn’t up to snuff. Reliability is key and fiber lasers offer just that, with fewer adjustments to make and specific wavelengths used to do the cutting.

Additionally, fiber lasers are significantly more powerful, meaning they can work quicker and more efficiently, especially when it comes to highly-reflective materials such as copper. These quick turnaround times cut down on labor costs and allow the user to ger more work done in a shorter period of time. This efficiency will also reduce the amount of energy used, which should also reduce energy bills. Perhaps best of all: these lasers require far less set up and maintenance than traditional ones do.

If you are in need of laser cutting services, Fireblast Global is here for you. We can offer you short lead times and will give you a quote in a timely manner. Call 800-716-1977 to learn more today.